This trend marks the last two years: food and beverage companies that sell their products without packaging. In Germany, there are about 70 companies like these, and the trend is increasing. However, this is still a niche market, as packaging with product information is an important factor for consumers when deciding whether or not to purchase the product. Compliance plays an important role and is key for guaranteeing that the labels and product information meet customer demands. Read more here about meeting compliance and how that benefits manufacturers in the food and beverage industry.

Generally, compliance means adhering to legal regulations governing the food and beverage industry and further implies that companies establish individual and voluntary codices. Compliance also means that all products that are introduced to market meet local country-specific requirements. The basic idea behind compliance is to ensure the wellbeing and protect the health of customers, and to avoid misleading or false information.

The overarching goal of compliance

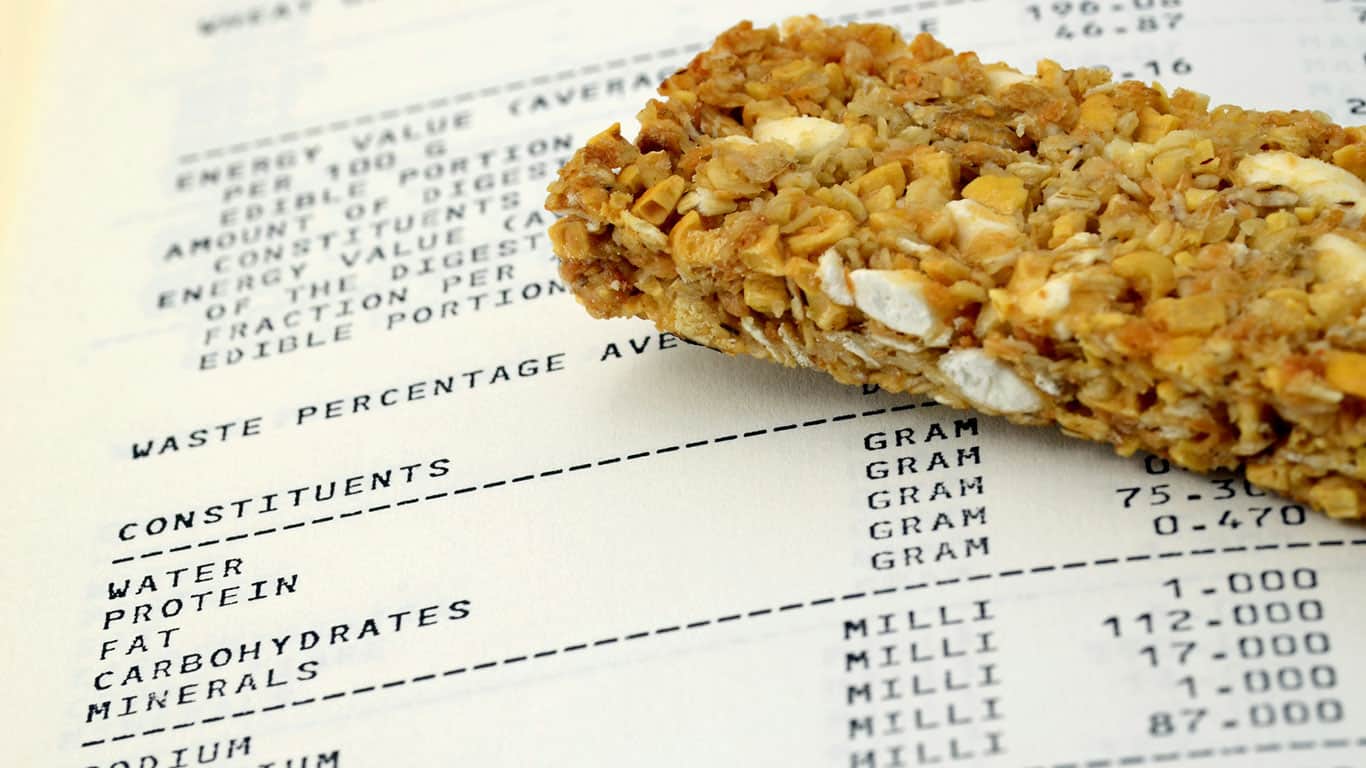

The reasons a customer decides to purchase a product correspond to various factors. Maybe the customer is drawn to the packaging, or the customer is already familiar with the product, and is convinced of its quality or simply curious. Studies from the 2017 nutritional report issued by the Ministry for Consumer Protection, Food and Agriculture have found that 89 percent of all Germans place heavy value on a healthy diet. Hence, it is understandable that they are often looking at the nutritional information and reading the ingredients on packaging to determine which product they will put in their shopping carts and will end up on their dining room table. A steadily increasing number of consumers today want to know what their food is made of, when it was produced and how long it will last.

In addition, they want to know about the sugar and fat content, and how many calories their food contains. This information plays an important role in making purchasing decisions – especially when special dietary restrictions are to be calculated into the consumer’s meal plan. Also, allergy and intolerance considerations require explicit ingredients labelling on products. This is the imminent task of the food and beverage industry: according to findings by the Robert Koch Institute, nearly 30 million people in Germany suffer some kind of allergy. Therefore, it is crucial that specific labelling concerning allergens appears on product packaging. In so doing, compliance determines to what extent the consumer make conscientious purchasing decisions.

Free E-Book

Regulations, Speed-to-Market and Innovation: How to stay compliant and competetive in an ever-changing market place.

Know what’s in it

Without corresponding descriptions on product labels, the consumer does not have any way of knowing what he or she is buying. This decision can only be made based on what the label is telling the consumer about the product. The advantage for the consumer is simultaneously a challenge for the food and beverage industry, since compliance specifically stipulates which ingredients must be included in the product labeling and how they should be described. In the European Union, this means the “Big Seven,” the major specifications that are required to be given on any label. Since December 13, 2016, the EU specifically requires all manufacturers to label packages with specifications related to calories, fat, saturated fatty acids, carbohydrates, sugar, protein and salt content in proportions of 100 grams or 100 milliliters of the product, visibly displayed in the label in order to make it easier for the customer to allocate the product according to their nutritional requirements.

In addition to the EU, most other countries set the daily nutritional allowance units to 100 grams. This enables consumers to also compare products internationally. The USA is an exception to this rule, where labels must include data about how many calories the product contains per portion. Therefore, many manufacturers specify all nutritional information in the same way, per portion. Despite country-specific differences, the overarching goal of compliance is still to provide the consumer with the best information possible and thereby to engender trust between the manufacturer and the consumer.

The challenge for manufacturers

Businesses who wish to permanently position themselves on the food and beverage market and remain competitive must ensure that they are at all times compliant with all product requirements. In Europe, there exists since 2014 a correlation in this context between rules and specifications which simplify product data management in enterprises. Developed by the European Food Safety Authority, the European Food Information Regulation 1196/2011 requires manufacturers to facilitate consumer access to all relevant product information when purchasing food and beverage items. Throughout Europe, standardized norms for product specifications are aimed to make this process easier.

Along with guidelines concerning size and positioning of the print on the package labels, the European regulations require that the origins of all meat and use of additives are to be denoted and made visible by highlighting. Keeping a handle on these specifications can quickly become daunting for businesses, particularly when it comes to keeping up-to-date on the current laws, as the regulations are changing fast to meet demands on the part of EU institutions and consumer agencies, often implying new requirements which must be implemented quickly. For example, unlike before, allergens must now be listed on the package label in bold. Another new regulation is that the botanical origin of vegetable fats must also be included. Therefore, in order to stay up-to-date, companies can no longer rely on doing their own research.

Using PLM software to remain compliant

You can no longer stay competitive by manually carrying out updates, implementation and documentation of all legal requirements. Both the changing consumer demands and the push for speedier product development cycles are leading to increased data volumes. Manually processing these data costs companies time and money and also increases sources of error. Profitable processes are different. To achieve compliance, a software application is essential. A manufacturer who uses automated processes throughout the entire production process until completion of the final product has a clear advantage. The solution: a digital production lifecycle management (PLM) software.

PLM solutions enable manufacturers in the food and beverage industry to manage all product specifications using a single integrated system. Throughout all operational areas of an entire enterprise, any updates are implemented dynamically and in real-time. From the ingredients to the final product, a proper PLM system compiles a reliable report which includes all important information. Along with the ingredients, these reports also incorporate the origin, geographic details and language information. Thus, a PLM system ensures that when generating product labels, all required specifications are processed and are up to current compliance standards.

In addition, PLM systems work according to international legal guidelines concerning ingredients and nutritional information, ensuring alignment with local requirements wherever the final product is brought to market. In so doing, a PLM solution incorporates the specifications of all the countries supplied by a given provider, and prints labels in the corresponding language. In this way, the manufacturer meets compliance guidelines and provides consumers around the world with a decisive advantage: they are fully equipped with ample information based on which they can make conscientious purchasing decisions about the products they are buying.