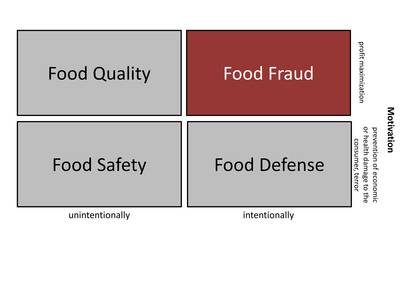

What Is Food Fraud?

Food Safety Net Services (FSNS) defines food fraud as: “the act of purposely altering, misrepresenting, mislabeling, substituting or tampering with any food product at any point along the farm–to–table food supply–chain. Fraud can occur in the raw material, in an ingredient, in the final product or in the food’s packaging.” From the 1981 olive oil scandal, where the hazardous chemical aniline, mixed with rapeseed oil, was masqueraded as the coveted oil by street vendors across Spain, to the 2013 horsemeat scandal in the UK, throughout history consumers have had more than enough reason to think twice before believing everything they read on the packaging.

Food fraud cost

Food fraud is estimated to cost the world economy $48 billion per year. The University of Minnesota National Center for Food Protection and Defense has approximated that about 10% of US food could be adulterated.

Free Whitepaper

Product Lifecycle Management: Learn how to drive innovation, reduce costs and risks and eventually gain a competitive advantage.

Why is food fraud happening? Some factors include:

- Increasingly complex supply networks being incorporated into ever fewer multinational chains

- increasing supply prices

- the considerable improvement of shifting methods and long-term storage of perishable goods.

The Response: Food Defense

According to the Food and Drug Administration, “food defense is the effort to protect food from acts of intentional adulteration.”

Regulatory agencies strengthen food defense

The FDA’s Food Safety Modernization Act (FSMA) final rule, published last year, aims at preventing intentional adulteration, “while not likely to occur, could cause illness, death, economic disruption of the food supply absent mitigation strategies.”

How can the Food and Beverage Industry join regulators on the frontlines of Food Defense?

1. Improve external collaboration

A transparent end-to-end supply chain is crucial. Companies must work together with their suppliers to forge long-term relationships beyond just what is required by governments and international agencies. They much surpass the bar set by auditors. Both manufacturers and retailers must catalog and index supplier registers, particularly those that are producing the main recipe ingredients. Intelligent collaboration with stakeholders includes reviewing procurement contracts and ensuring that there are stringent regulations in place against misrepresenting ingredients.

2. Know your products

Knowing your supply chain each step of the way, from farm to shelf, is also crucial. Companies must collaborate with their suppliers to build long-lasting partnerships that surpass the regulatory standards to go the extra mile in ensuring the utmost safeguards for public food safety.

3. Keep innovating to improve traceability & claim/recall processes

Traceability is key to fighting food fraud. Being able to catalog and index each ingredient, one at a time, from farm to shelf, and each step along the way, is equally important. To guarantee that systems and procedures are in place to implement optimal traceability, companies should be up-to-task by accounting for realistic scenarios and performing frequent audits, especially for high-risk and for main ingredient products.

4. Consumer complaints and any voiced public concerns should be taken seriously.

Registering complaints in a database, responding to them in a timely and efficient manner, and tracking the procurement processes involved in defective products are the first steps to sound food defense. This first line of food defense means that food and beverage enterprises should always be ready for potential product recalls, to do whatever it takes to minimize any risk to public health and brand reputation. the negative effects to human health and brand reputation for food and beverage companies involved. Preemptive emergency procedures already set in place before any unfortunate incident can happen should always be a significant component of any food and beverage enterprise’s risk management program.

What is the best tool to ensure that your food and beverage company is on the frontline of food defense?

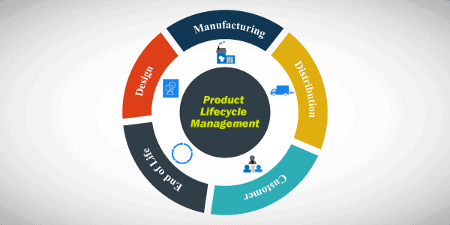

Enter Product Lifecycle Management (PLM)

As you can see, food fraud is of utmost importance for management level cross-functional control in any food and beverage enterprise. This includes seamless and efficient synchronization between the operational, procurement, sales, research & development, quality assurance, and marketing departments to be sure to provide consumers the products they ask for and expect to eat. This type of management is best handled by Product Lifecycle Management. One of the best solutions is a Software-As-A-Service that SpecPage can provide to the food and beverage industry. One of our PLM’s major pillars is tracking product traceability. SpecPage enables materials and recipe specifications management to do just that throughout the entire product structure and lifecycle.