Companies in the food and beverage (F&B) industry face the challenge of innovating to meet the evolving needs of consumer segments, staying compliant with complex regulations, and maintaining their competitive edge by ensuring consistent quality and improving time-to-market.

A company that manufactures salty potato chips, a perennial favorite, operates in a saturated market where healthier (ex: baked chips) or better-tasting (ex: salty with a cheesy twist) or better marketed (viral or extremely popular ads that resonate with a particular demographic) all pose competition. Besides these factors, the operational efficiency of the manufacturing process determines product success and profit margins. An organization with an innovative idea for a product may fail to monetize its full potential if its manufacturing processes are neither time- nor cost-efficient.

Free Whitepaper

Product Lifecycle Management: Learn how to drive innovation, reduce costs and risks and eventually gain a competitive advantage.

There is a consensus among F&B industry participants that fulfilling strategic business goals will be extremely difficult unless a robust product lifecycle management strategy is in place, which meets regulatory and competitive challenges.

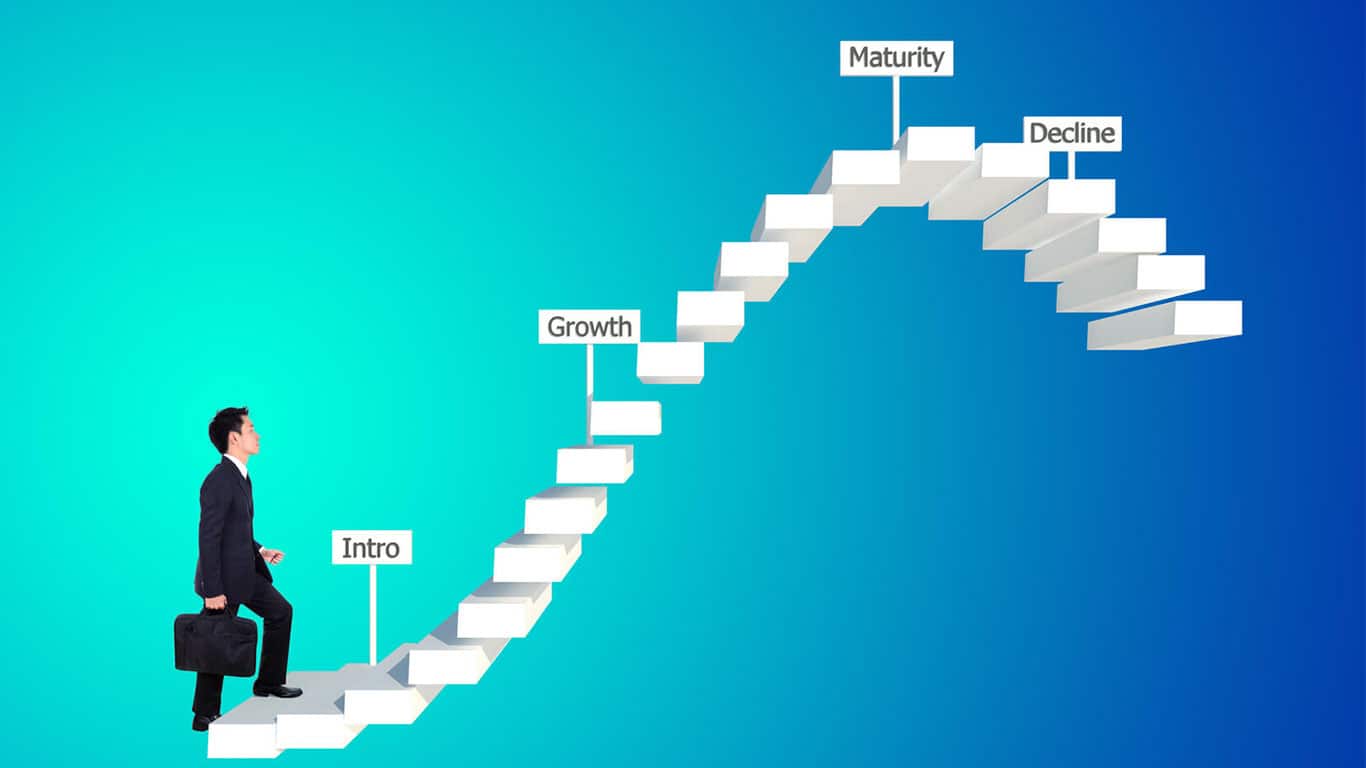

What does a product lifecycle look like?

- Product design and development

- Launch of the product in the market

- Growth in product sales post-introduction

- Gradual plateauing of product sales

- Market saturation characterized by a decrease in profits

- Decline in product where the buyer base falls drastically

With these steps in mind, a judicious review can provide a conclusive explanation as to why a product may fail.

- The ‘sameness’ of the product in a sea of similar competitors is bound to create indifference or abandonment in favor of new or more interesting entrants.

- The development costs – which are high to begin with – could be miscalculated or mismanaged. When profits are lower than development costs, the product may cease to be viable (unless an appropriate solution is implemented to control costs).

- Product marketing may not be effective enough – a product is bound to be forgotten and overtaken by better-marketed counterparts unless there are targeted marketing campaigns that encourage people to try out the product soon after it launches.

Now let us look at these points in more detail and discover an integrated solution that can help companies bring out better products and deploy a more efficient development framework that delivers cost savings.

Five cornerstones for optimization

1. Project and Portfolio Management

On their own, great ideas cannot achieve anything; they must be translated into action, bringing together processes and handled by the right mix of experts as they pass through conception to development and launch. The problem is, all the data involved in bringing a product to market often tends to reside in siloes. Even the activities are not as efficient as they can be, with users spending too much time accessing many different datasets.

By optimizing for time and productivity, product development cycles can be cut shorter to improve time-to-market and allow Research and Development to quickly get back to work on developing the next innovation.

Solution: A product lifecycle management (PLM) software that improves data search and staff collaboration can increase staff productivity by a significant margin.

2. Material and Recipe Management

Monotonous and repetitive tasks are increasingly being automated to minimize or eliminate error rate, and allocate human talent to innovation and profit-generating tasks. In the F&B industry, material and recipe management is stuck in the past. Manual entries and modification of data inevitably leads to inaccuracies and wasted costs. Duplication is a major issue, with data being recorded multiple times, as raw materials and specifications are recaptured and reintroduced into the database instead of reusing and/or modifying already existing datasets.

As a result of these inefficiencies, recipe information is not reactive to consumer or partner demands. Physical archiving also makes data difficult to access for immediate query and use when needed.

Solution: A comprehensive, cross-product data system that enables manufacturers to adapt and update material data and recipes easily, keeping costs low and supporting the agile development of innovative products.

3. Specifications Management

Specification data tends to be maintained in siloes. Not surprisingly, inaccuracies can creep in, resulting in bothersome management of incomplete or wrong data. Updating data becomes even more cumbersome when the specifications need to be managed in different languages. When standard specifications are affected, it often comes at the cost of product quality.

Solution: PLM software offers companies a single data platform that can be modified and updated by different departments. It can help prevent lost, misplaced or unapproved documentation and specifications. Timely and accurate specifications can not only support internal product quality standards but also assist with regulatory compliance.

4. Supplier Management

Supply chain management is a core strategy essential to getting products more profitably to market. A key problem in this regard is the lack of any quick mechanism to trace back the supply chain – besides the continuing practice of manually recording supplier data – which can compromise product quality and compliance.

Solution: PLM software that allows companies to standardize acceptance criteria, which can improve the accuracy and efficiency of data management, while also creating greater transparency across manufacturing and other related functions. The software can automate cross-functional workflows, and data can be transferred electronically between suppliers and producers. Companies can publish standardized documentation – including specifications and certificates – to ensure that suppliers meet their requirements.

5. Packaging and Labels

Surveys have indicated that most shoppers make it a point to read ingredient and nutrition labels, and admit that taste, nutrition and product safety are important considerations in making food purchases. Companies need to adapt packaging and labels to stringent regulatory requirements, while also ensuring that the labeling appeals to consumers. This is a multi-faceted process demanding collaboration between engineers, designers and marketing managers.

Solution: PLM software that makes the labeling and packaging process quicker and more streamlined.

PLM software integrates product development processes, people, data and business systems, providing an instantly accessible, easily searchable warehouse to save time, improve productivity, enhance quality and boost collaboration between and within companies. By solving problems and aiding better performance across beginning-of-life, mid-life, and end-of-life products stages, PLM is a high-ROI investment for any F&B manufacturing process seeking to be lean, efficient and profitable.

Photo Credit Featured Image: © fotolia / geargodz